Varidhi is a leading provider of complete manufacturing services ranging from Printed Circuit Assembly to Complete System Integration and Box Build. Our services range from prototyping to highvolume production. We specialize in.

Varidhi is a leading provider of complete manufacturing services ranging from Printed Circuit Assembly to Complete System Integration and Box Build. Our services range from prototyping to highvolume production. We specialize in.

We specialize in quick-turn services for highly complex and advanced PCB assembly and systems manufacturing in meeting dynamic business needs.

Varidhi has competent engineering and manufacturing team to help many customers to give complete solutions all kinds of PCB assembly requirements:

We mount a wide range of electronic components which include

We ensure end-to-end solutions to organized sector in the domain of

Engineering services in PCB Assembly

Varidhi provides an end-to-end manufacturing service that extends well beyond just PCB assembly. Varidhi is fully capable of delivering fully packaged, integrated and tested products.

Varidhi provides an end-to-end manufacturing service that extends well beyond just PCB assembly. Varidhi is fully capable of delivering fully packaged, integrated and tested products.

Highly skilled engineering team and experienced workforce with state-of-the-art Infrastructure & high technology equipment ensure that every system build meets the highest standards of workmanship, quality, and reliability. Varidhi has the expertise and flexibility to produce complete system box builds for a wide range of industries and applications, from Aerospace, Automotive, Consumer, Defense and Military, medical and industrial and Telecommunications sector and more.

Varidhi has expertise in manufacturing from a full range of sub-assembly, box-build and final system integration solutions. Our manufacturing processes are designed and configured according to each customer and product, ensuring that our capabilities suit customer needs, while the tight integration of the entire production process maximizes flexibility, lowers cost, and reduces time to market.

Specific system assembly offerings include:

System build capabilities include:

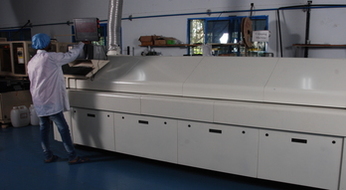

Varidhi has a wide array of state-of-the-art Manufacturingecosystem with high technology machinery and testing equipmentand our unique approach to customer interaction, process design and life cycle management enableVaridhi to be perfectly equipped to service the most demanding of customers.

Varidhi has a wide array of state-of-the-art Manufacturingecosystem with high technology machinery and testing equipmentand our unique approach to customer interaction, process design and life cycle management enableVaridhi to be perfectly equipped to service the most demanding of customers.

Varidhi has successfully executed numerous projects of high-mix, low, Medium and High Volume with world class manufacturing environment into a predictable, reliable, flexible, demand-driven operation through manufacturing excellence models

Varidhi provides Flexible, Scalable Manufacturing Solutions, low cost and high quality total satisfaction to Customers

At Varidhi, both customers and human resources are considered to be the stepping stones of success, and represent the cumulative progress of the organization, a consequence of which rolled out as seasoned customer relationships and enhanced bonding with our team.