Prototypes are an essential component of product development. Prototyping provides an in-depth look into the product and allows the customer to perform an analysis of the product’s components.

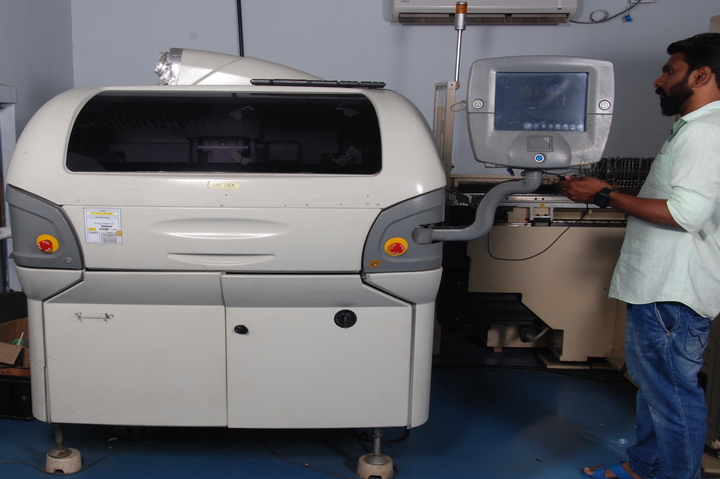

Varidhi understands the importance of responsiveness and flexibility during any prototype activity. It provides experienced prototyping and new product development services from new product introduction (NPI) to Low, Medium and High volume manufacturing.

Finalizing product designs with production in mind is a critical step in optimizing the time, resources and cost of actual production.

Varidhi always has manufacturability and testability inOperational process, and we provides the design review services critical to ensuring that issues relating to cost, quality and efficiency

At Varidhi, DFM and DFT are continuous activities that will follow your products through development, production, and redevelopment to ensure that improvements can be realized from one generation to the next.

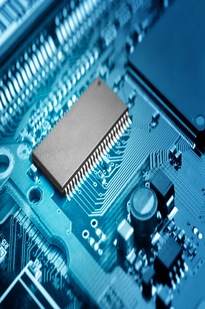

Design for Manufacturability (DFM) is the front-end process for electronic products which focuses on minimizing the cost, complexity, defects and production time of the product-specific volume manufacturing process.

Design for Manufacturability (DFM) is the front-end process for electronic products which focuses on minimizing the cost, complexity, defects and production time of the product-specific volume manufacturing process.

Before taking the product to the volume production stage, Varidhi engineering & production team will inspect and evaluate products for manufacturability, from individual components to the entire production line. Varidhi aims to reduce complexity and eliminate manual operations wherever possible, while creating procedures and fixtures that minimize variation and human error. Continuous engagement with your product design team allows us to ensure that a final design will both satisfy Customers specifications and quality.

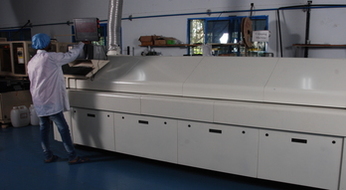

Throughout the design review process, Varidhi strives to create a testing strategy that will not only prevent defects from leaving the lines, but also ensure that problems are detected at the earliest opportunity and resolved at the lowest cost.

Throughout the design review process, Varidhi strives to create a testing strategy that will not only prevent defects from leaving the lines, but also ensure that problems are detected at the earliest opportunity and resolved at the lowest cost.

Our DFT reviews are performed at both product and system levels. Varidhi works with Customer’s design engineers to optimize product and materials for each step of the overall testing strategy so as to ensure a seamless integration between the testing and manufacturing work-flows.

At Varidhi, both customers and human resources are considered to be the stepping stones of success, and represent the cumulative progress of the organization, a consequence of which rolled out as seasoned customer relationships and enhanced bonding with our team.