Vinyas drives innovation in SCM with integrated value chains with focus on core competencies and improves Manufacturing scheduling and forecasting.

Varidhi has strong relationships with component manufacturers and distributors, to provide complete materials planning, purchasing, and warehousing to maximize Customer savings and minimize Customer liability. The supply chain management engineers will enable supply-demand matching, distributed order management, leveraged contract visibility and reduce gaps between forecasts and plans.

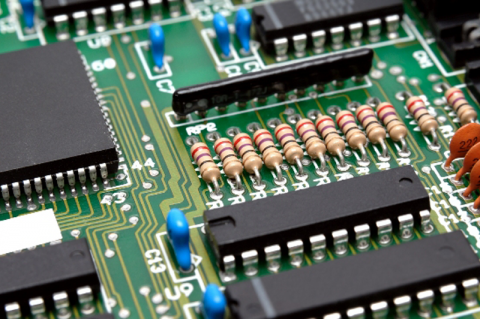

Vinyas delivers significant business value through strategic sourcing, as a turn-key or consignment contract manufacturer, Customers will find value in our approach to materials management, from planning, procurement to inventory control.

Vinyas delivers significant business value through strategic sourcing, as a turn-key or consignment contract manufacturer, Customers will find value in our approach to materials management, from planning, procurement to inventory control.

The global procurement database allows Vinyas to leverage our entire network, enabling to provide Customers with total flexibility at a competitive price.

The materials planning team is the window through which customers can manage consigned parts and acquire materials through Vinyasnetwork. Vinyas leverage experience in materials planning and access to a global network to help customers to significantly cut their costs. The expertise in sourcing engineering and component functions allows Vinyas to frequently suggest lower-cost alternatives.

Vinyas has strategic sourcing environment, whilecollaborated with global network of suppliers to provide lowest possible material cost and better quality and deliverability. The strong supplier network relationships allow Vinyas to optimize material availability, creating value for overall supply chain and superior customer satisfaction

Vinyas realizes the importance of stability in a supplier partnership. our long-term partnerships with strategic suppliers allow Vinyas to reduce cost, ensure quality and deliverability on time.

Vinyas realizes the importance of stability in a supplier partnership. our long-term partnerships with strategic suppliers allow Vinyas to reduce cost, ensure quality and deliverability on time.

Vinyas constantly evaluates suppliers to clearly understand the quality system and production processes employed by both existing and potential suppliers. Vinyas is able to immediately identify problem areas that need to be addressed, thus reducing potential risk by ensuring the effectiveness and stability of our suppliers' operations.

Vinyas works actively with our core suppliers to ensure that they continue to deliver the value and quality sought by customers. Vinyas has implemented SPC control/analysis and continuous improvement programs, and conduct periodic quality reviews and on-site support to maintain an uncompromising level of quality in the materials.

Vinyas conduct periodic reviews of supplier performance workbench based on the quality, cost, delivery and flexibility of past shipments. The results are used by our quality engineers and material planning team to appropriately update supplier strategy and implement plans for improvement. This evaluation offers a 360-degree insight into the entire supply chain.

Vinyas has developed a technique and methodology to measure supplier performance and develop suppliers, thereby, reducing supply chain risk by setting performance benchmarks and evaluating suppliers against the set parameters

Based on the results of performance evaluations, Vinyas may conduct audits of suppliers on a regular basis to understand the root cause of problem, and implement improvements to meet the quality demands of both Vinyas and customers.

Vinyas drives innovation by transforming their traditional supply chains into integrated value chains, byproviding seamless and holistic solutions that are designed to meet best in class solutions with industry-specific functionality.

At Varidhi, both customers and human resources are considered to be the stepping stones of success, and represent the cumulative progress of the organization, a consequence of which rolled out as seasoned customer relationships and enhanced bonding with our team.